2022-02-23 Product news

Introducing the new Alfa Laval AC540 family of brazed plate heat exchangers – four new high-efficiency models, designed to work with the low-GWP refrigerant of your choice

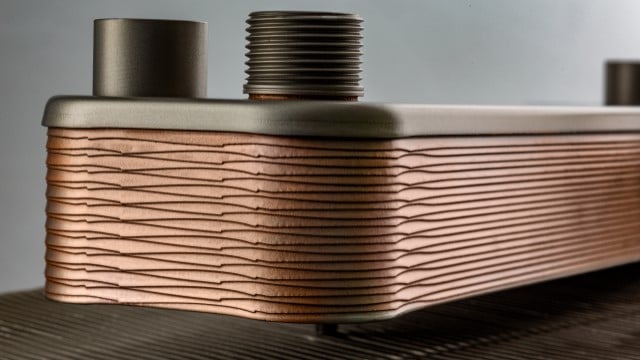

Alfa Laval launched the new Alfa Laval AC540 brazed plate heat exchanger at their first online net-zero launch event, where they showcased new, cutting-edge thinking in energy-efficiency, clean energy, and circular-economy solutions. To address the many changes that are reshaping the rapidly-evolving world of refrigerants, Alfa Laval developed the Alfa Laval AC540 family of brazed plate heat exchangers, with designs that are specifically optimized to work with R32, carbon dioxide, and other low-GWP refrigerants.

Environmental concerns and legislation aimed at addressing climate change are challenging the HVAC industry to increase its focus on enhanced performance and improved energy efficiency and to rethink its choice of refrigerants.

Increasing the use of low-GWP refrigerants, including natural refrigerants such as propane and HFCs such as R32, is one key aspect of addressing climate impact. Another important aspect is reducing the energy required per unit of cooling. The AC540 family is targeted to do both, in a kW range designed to meet the requirements of system builders.

CO2 is also gaining prominence in the market, having become the norm in commercial refrigeration applications, such as in supermarkets, and also has benefits in other applications, including large-capacity chillers and large heat pumps.

The Alfa Laval AC540 family of brazed plate heat exchangers was designed to meet these challenges

In terms of size, capacity and place within our offering, the AC540 family falls between the AC502 and the AC1000 and is ideal for use with multiple scroll chillers from 250-800kW. It is 750 mm high and 400 mm wide and works with a wide range of high-density, low-GWP refrigerants.

The AC540 family incorporates unique, cutting-edge features, including DynaStaticTM distribution, which can be optimized for a specific application and refrigerant, and IceSafe, which helps our customers manage freezing. The 540 family also features FlexFlowTM and PressureSecure, which enables reliable operation even at very high pressures.

“Alfa Laval invests heavily in product development, and our focus on innovation is really apparent in this new family of brazed heat exchangers. The unique asymmetric plate design of this family makes it possible to minimize the evaporator’s refrigerant charge and also reduces the pressure drop on the secondary side, making it possible to use a smaller pump, which lowers electricity consumption and reduces overall costs,” says Fredrik Ekström, President, Business Unit Brazed & Fusion Bonded Heat Exchangers.

The 540 family includes four models, all of which are manufactured at Alfa Laval’s new, state-of the-art factory in San Bonifacio, Italy.

- The ACK540 is a high-capacity unit that offers exceptional thermal performance making it ideal for evaporation duties in HVAC applications.

- The ACH540 is similar in design to the ACK540, but with a design pressure of 48 bar, it is more suitable for use with other high density refrigerants.

- The CBP540 can be used as a flooded CO2 evaporator, making it possible to extend the benefits of plate technology to duties that were traditionally limited to shell & tube heat exchangers.

- The ACP540 is optimised for CO2. It functions as a DX evaporator for use in subcritical cascade systems.

The 540 family is a great addition to Alfa Laval’s comprehensive portfolio of efficient, innovative and sustainable solutions. And of course, just like all of our products, they are supported by a worldwide network of experts who truly understand our customers’ business needs.”

To learn more about the AC line of brazed plate heat exchangers, please visit:

AC brazed plate heat exchangers

For further information, please contact:

Therese Tonning, Marketing Communication Manager

Business Unit Brazed & Fusion Bonded Heat Exchangers, Energy Division, Alfa Laval

Phone: +46 46 36 72 09

E-mail: therese.tonning@alfalaval.com

Editor’s notes

Brazed plate heat exchangers

Alfa Laval copper-brazed plate heat exchangers are a compact, efficient and maintenance- free solution for heating, cooling, evaporation and condensing in numerous applications. Each unit is designed for duty optimization, with a range of unique features that ensure both superior thermal performance and maximum reliability. This enables the longest possible service life – even under conditions with extremely high design pressures. An ideal solution for use with natural refrigerants, thanks to the compact footprint, optimized plate design and high design pressure.

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing better™.

Alfa Laval has 17,900 employees. Annual sales in 2021 were SEK 40.9 billion (approx. EUR 4 billion). The company is listed on Nasdaq OMX.

Les échangeurs thermiques à plaques brasées en cuivre Alfa Laval constituent une solution compacte, efficace et sans entretien pour le chauffage, le refroidissement, l'évaporation et la condensation dans de nombreuses applications.

Solutions d'échangeurs thermiques à plaques brasées

Downloads