Petrochemical solutions

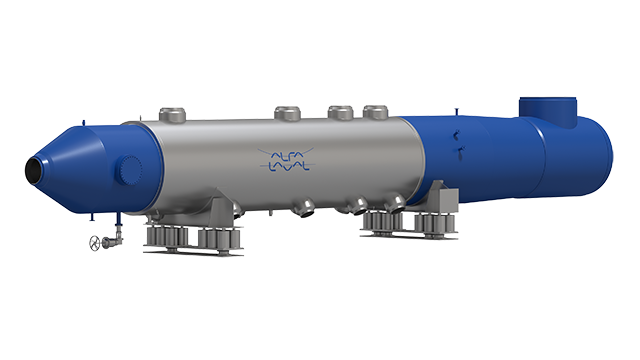

Petrochemical producers want reliable and sustainable performance. With the broadest range of compact heat exchangers and specialized shell-and-tube heat exchangers, Alfa Laval provides cost-effective energy recovery. But that is not all. With the right solution, you can improve your heating, cooling, condensing, and re-boiling duties. This boosts profitability while reducing costs, floor space, and emissions at the same time.

Our best sellers

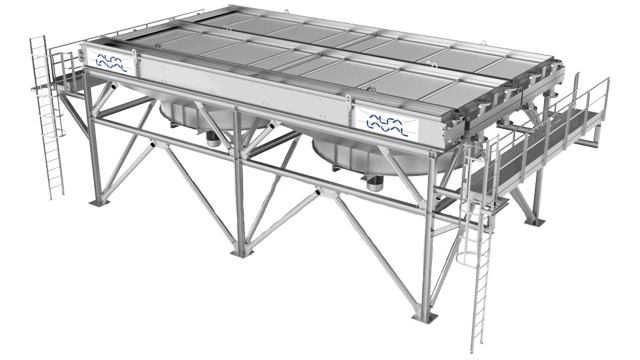

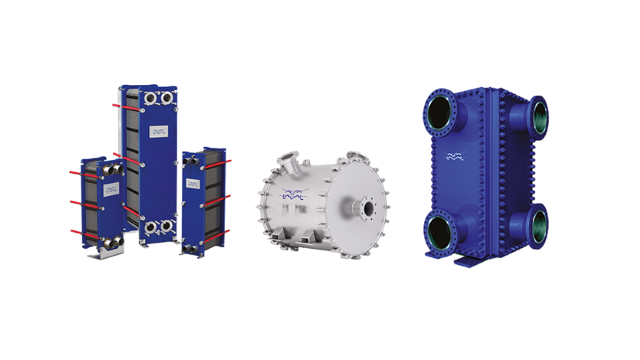

Compabloc

All-welded and fully accessible, the Compabloc can handle tough duties that need high pressures and temperatures. It can even cope with the most aggressive inlet media without compromising on fast and easy cleaning or inspection. Its flexible connection size and placement can manage asymmetric flows, and work in combination with a short plate construction to make the perfect solution for condensing and re-boiling duties.

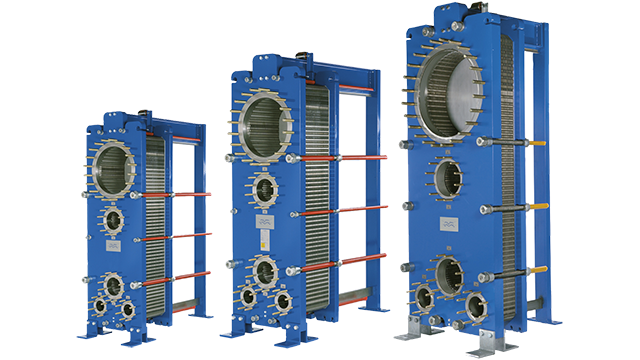

Gasketed and Semi-welded plate heat exchangers

Alfa Laval’s offers a full portfolio of gasketed plate heat exchangers that come in a wide range of shapes and sizes. This makes it possible to tailor each solution to fit any given duty. All designs can easily be adjusted to fit new conditions by removing or adding plates to the chosen plate pack. But that is not all, simplified dismantling and cleaning procedures make these heat exchangers very serviceable. Simply add the semi-welded concept to handle aggressive media on one side.

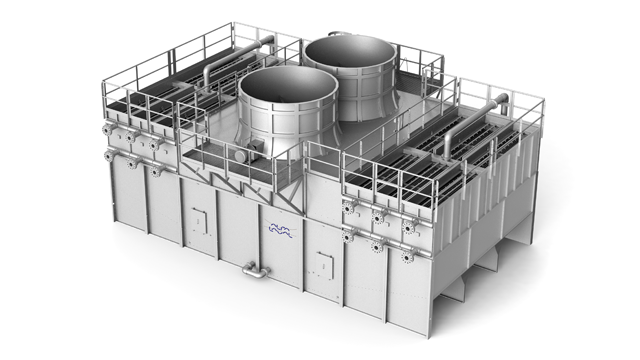

Spiral heat exchangers

The spiral heat exchanger is our no.1 problem solver. With its single-channel arrangement, this heat exchanger is self-cleaning and able to handle high-viscosity fluids. This design is easy to access for maintenance, making it the perfect option for low operating costs and optimized plant uptime. It also makes it an outstanding condenser that utilizes the lowest possible pressure drop. It can even be top mounted to reduce the installation costs even further.