Whey treatment in plant-based protein processing

Production of plant-based protein requires lots of water, and many producers face high operating costs and, in the worst case, lower production capacity due to limited water supply.

Up to 70% of the water used in a wet fractionation process ends up in the whey stream. An Alfa Laval whey treatment system lets you recover most of your process water, reduce wastewater volumes, and extract valuable proteins and carbohydrates. In additions, these systems can easily be integrated with both new and existing plants.

Increase yield with protein recovery

Up to 30% of the dry matter in whey comprises soluble proteins, peptides, and other amino acid derivatives that cannot be extracted in the main production process.

These proteins have excellent digestibility and high market value. As a result, they can be used in a variety of products, such as high-quality protein powders, nutrition supplements, and health food products. They can also be used as functional ingredients in processed foods, providing texture, stability, and other desirable properties.

Recovering these proteins increases the overall output of your operations, improves your bottom line, minimizes waste generation, and contributes to the sustainability and circularity of your production processes.

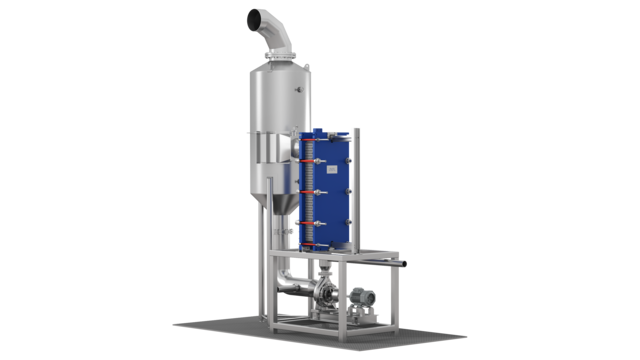

Alfa Laval offers advanced systems for capturing these proteins, either as coagulated proteins that can be separated by centrifugation or as functional proteins using membrane separation. These systems are designed to be efficient, reliable, and easy to use, helping maximize your output and profitability while minimizing your environmental footprint.

Produce and sell whey concentrate

Whey is a complex mixture of compounds such as carbohydrates, proteins, and salts. Instead of letting it go to waste, you can easily concentrate the whey and sell it as a valuable ingredient or precursor for additional processes. In addition, concentrating the whey reduces the effluent from the plant, minimizing the environmental impact of operations.

Whey concentrate can be sold as an ingredient for animal feed, providing a source of protein and other nutrients. Whey concentrate can also be used as a raw material in fermentation processes, where the sugars and proteins in the whey are converted into a variety of valuable products, such as biofuels, organic acids, and enzymes. A third use for whey concentrate is biogas production, where it is used for producing renewable methane.

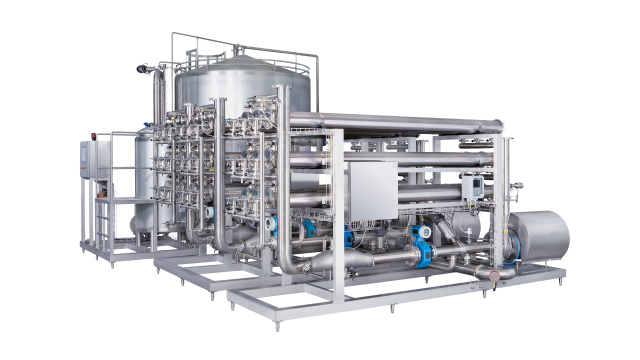

Alfa Laval offers evaporation and membrane systems optimized for whey concentration, and our application experts are glad to help businesses maximize efficiency and profitability while minimizing their environmental impact.

Water recovery and reuse

Around 70% of the water used in the protein extraction processes ends up in the whey stream, and recovering this water has a major positive impact on water consumption and sustainability.

Alfa Laval offers advanced evaporation and membrane systems for water recovery from whey streams. The recovered water can be used for cleaning purposes or polished further for potential reuse in the plant.

In addition to the environmental benefits, recovering water also reduces costs for purchasing and treating water and improves the economic viability of production processes.

Alfa Laval's evaporation and membrane systems are designed to be efficient, reliable, and easy to use, helping companies to maximize their water recovery and minimize their environmental impact.

Example of a whey treatment system

Fully tailored whey treatment systems

Fully tailored whey treatment systems

Depending on your operating conditions and requirements, our application experts will design a whey treatment system that meets your needs perfectly. The process chart above shows one possible example where protein, carbohydrates, and water are recovered. The benefits of this system include:

- Recovered water can be reused for flushing and CIP or in the main process.

- Increased yield thanks to protein recovery.

- Substantial reduction in wastewater volumes and BOD levels.

Operating principle

In the first stage of the process, the whey is heated using economizers and direct steam injection, causing the protein to coagulate. The coagulated protein is then separated from the liquid using a decanter and is thereafter sent to a dryer.

The liquid phase from the decanter is sent to an evaporation system where the water is boiled off, leaving a concentrate consisting mainly of carbohydrates and salts, which can be utilized in biogas or bioethanol production.

The condensed water from the evaporation system is purified using a reverse osmosis membrane system before being reused, either in the main process or for flushing or CIP.

The permeate (i.e. the filtered water) can be reused for cleaning, and the retentate (the rest) is sent to a wastewater plant.

완벽한 서비스 솔루션

서비스에 대한 시스템적인 접근 방식과 광범위한 프로세스 전문 지식을 결합하여 문제의 근본 원인을 파악하고 해결함으로써 전체 프로세스의 성능을 최적화합니다.

우리는 귀하의 공장 설비가 가동되는 한 전범위의 서비스를 제공합니다. 알파라발의 글로벌 서비스 네트워크는 거의 100개 국가를 대상으로 하여 신속하고 전문적인 지원이 항상 가능합니다.

투자 수익을 극대화하려면 알파라발과 서비스 계약을 체결하는 것이 좋습니다. 이 완전 맞춤형 서비스 솔루션은 예산 편성은 간소화하고 성능과 가동 시간은 극대화합니다. 귀하가 일상적인 업무에 집중하는 동안 알파라발은 귀하에게 필요한 서비스 조치의 계획, 조달 및 실행을 처리합니다.