Heating and cooling in the engine room

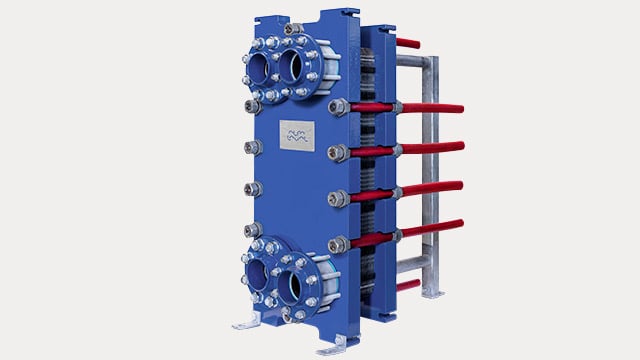

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Central cooling system

Cost-efficient removal of excess heat

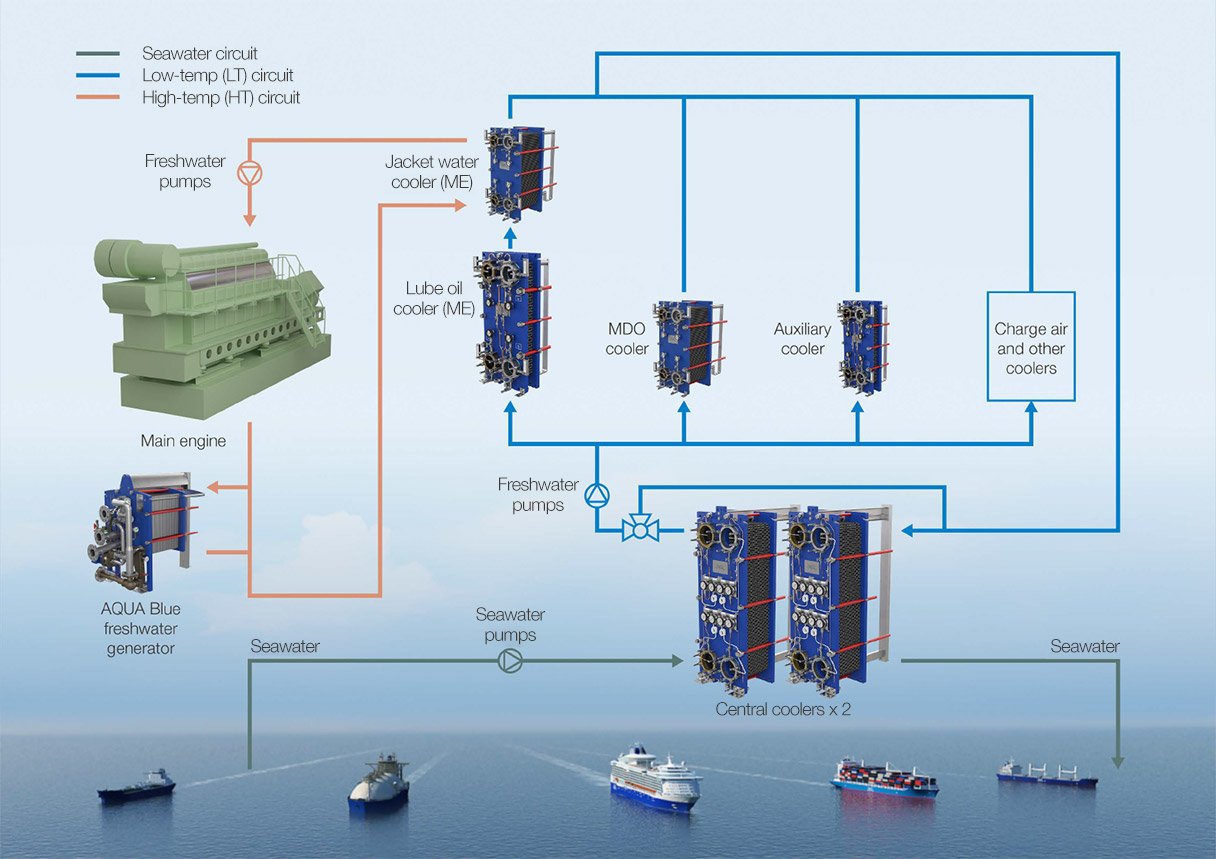

In the engine room, heat mainly needs to be removed from the jacket water cooler, lubricating oil cooler, diesel oil cooler and charge air cooler, along with the auxiliary engines and ancillary equipment.

The cooling flow of seawater is drawn from the sea chest. It passes through a coarse strainer to the titanium central coolers and thereafter overboard.

Fresh water is circulated through the central coolers, which are connected with a bypass regulation valve. The valve directs a portion of the fresh water through the coolers to maintain a constant temperature in the low-temperature circuit.

A portion of the excess heat generated in the jacket water circuit is used to generate fresh water in the Alfa Laval AQUA Blue freshwater generator.

Products

Services

알파라발 마린 서비스

글로벌 네트워크를 통해 진행되는 알파라발 마린 서비스는 설비의 가동 시간을 늘리고 성능을 최적화를 지원하며, 장비의 수명 전반에 걸쳐 신뢰감과 효율성, 컴플라이언스를 제공합니다.