Triple-E's 환경 솔루션

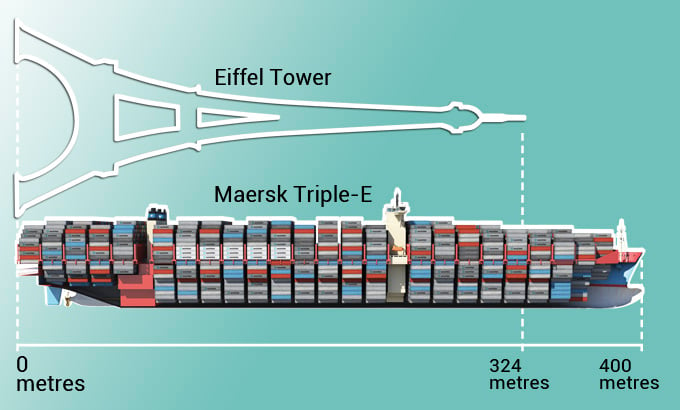

Triple-E의 규모는 놀라울 정도입니다. 무게는 60,000톤이고 길이는 400m로 누워 있는 에펠탑보다 76m 더 깁니다. 6월에 진수된 머스크라인의 이 새로운 선박은 세계에서 가장 큰 선박이자 역설적으로 가장 친환경적인 선박 중 하나입니다.

날짜 2024-06-13 글쓴이 Cari Simmons![]()

The Triple-E is not only the largest ship in the world, but also one of the greenest on the seas today. It emits three grams per tonne of goods per kilometre, which is much less than the average container ship emissions of 10 to 20 grams.

Jacob Sterling, Head of Environment & CSR at Maersk Line, points out that alternative modes of transport for long distances, such as air freight, are far less environmentally friendly. "Ocean freight is the most energy-efficient way of moving goods. You can't get such economies of scale with trains, trucks or airplanes."

Maersk's goal was to make a ship that was 30 percent more energy and cost efficient than its previous ships. A long-term perspective was applied, says Heimann. "We applied the same line of thinking as when investing in, for example, low-voltage light bulbs," he says. "You pay more initially, but get longer lifetime and a lower electrical bill and since fuel prices are unlikely to fall, this approach makes for a better business case."

Optimal design

Economies of scale were applied to the Triple-E: the more containers that fit in, the more efficient the journey. Achieving such a high capacity required some design adjustments. The Triple-E’s hull, for example, is U-shaped and more spacious than traditional ships to accommodate one extra row of containers.

The engine room was put at the rear of the ship, instead of in the middle, which is the traditional solution. “By doing this, we are able to fit in more containers behind the navigation bridge and in the hull. It might be a little inconvenient, due to a longer passage to the engine room, but it’s not what we consider a problem,” says Heimann.

A waste heat recovery system, which uses Alfa Laval boilers, helps propel the ship by capturing energy from the engine’s exhaust gas. This cuts fuel by up to 10 percent.

The energy is also used to, among other things, produce electricity for the onboard accommodation. The waste heat recovery system has allowed the Triple-E to use a smaller and less energy-consuming main engine.

The Triple-E has a “twin-skeg” propulsion system with two engines driving two propellers. The ultra long-stroke engines in the twin-skeg configuration operate with a lower number of revolutions compared with a traditional engine. This system will generate further energy savings of 4 percent compared with a single engine and propeller system.

The new vessels also include Alfa Laval’s PureBallast 3.0, which is the latest and most effective version of the water treatment system that uses UV light to protect against the threat of invasive species. Meanwhile Alfa Laval’s Aqua freshwater generators use vacuum distillation to convert seawater into high-quality freshwater.

Reduced speed key to savings

Triple-E travels an average speed of 17-18 knots and a maximum 23 knots, compared with the usual 25-knot maximum. Reducing the ship’s speed was a major energy-saving factor. “This significantly reduces the ship’s power requirements,” says Heimann. “With a reduction of only few knots, we can achieve a dramatic reduction in fuel consumption.”

Sterling says that customers have come to accept the extra delivery time. “They mainly want to know when the goods are coming and whether it takes 25 or 30 days. Customers today realize that we have to do what we can to save energy costs, reduce CO2 and remain profitable.”

Customers require sustainable transports

Many of Maersk's customers are big companies with global brands like Nike, BMW and Heineken. They share a strong interest in sustainability and, as Sterling says, “are interested in the results of our efforts”. Maersk promises to continue reducing CO2 emissions and set strong targets. When Maersk’s five-year-old target to reduce its CO2 emissions by 25 percent was achieved earlier than expected, it was quickly upped to 40 percent, from 2007 to 2020. “We wanted something to work towards,” says Sterling. “The current focus is on improving fuel efficiency.”

Compared with the industry average, Maersk is already more fuel efficient, emitting 10 percent less CO2 in 2012 than the competition, which adds up to a total savings of 2.1 million tonnes of CO2 for all Maersk Line’s customers."

JACOB STERLING, HEAD OF ENVIRONMENT & CSR AT MAERSK LINE

"We are continuously learning about technologies and developments that can make the next project even more efficient and environmentally friendly. It's amazing how much was achieved on the Triple-E with existing technologies in terms of CO2 reductions. Imagine when we start using solar, biofuels or other alternative energy sources. With more breakthrough development on the renewable energy side there will be so much more to come."

지속가능한 발전 목표에 기여하는 알파라발

UN(국제연합)은 인류가 지향해야 할 17개의 '지속가능한 발전을 위한 2030 아젠다' 를 설정하였으며, 이는 모든 193개 회원국이 2030년까지 사회, 환경, 경제적으로 지속 가능한 세상을 만들기 위해 최선을 다해야 함을 의미합니다.

이 비전의 달성 여부는 이제 우리와 같은 기업에 달려 있습니다

CUSTOMER'S VOICE

Ocean freight is the most energy-efficient way of moving goods. You can’t get such economies of scale with trains, trucks or airplanes.

JACOB STERLING, HEAD OF ENVIRONMENT & CSR AT MAERSK LINE

Alfa Laval equipment onboard Triple-E

DID YOU KNOW...

..that airfreight emits about 500 grams of CO2 per tonne of goods? Using rail transport for the Triple-E's 18,000 containers would require the rather unfeasible option of having a 110-kilometre-long train.

..that the 400-metre-long, 59-metrewide vessel has a speed of 18 knots, with its cargo packed efficiently into 18,000 containers. E.

알파라발 고객 매거진 here

알파라발에서 발간하는 고객 매거진입니다. 흥미로운 다양한 스토리가 소개되어 있습니다.

Are you curious?

최고의 기술력으로 자연, 인간을 위한 최선의 방안을 추구하는 알파라발은 어려운 도전을 극복하기 위해 항상 노력해 왔습니다. 이는 호기심이 충만한 헌신적인 사람들만 있다면 충분히 달성할 수 있습니다. 호기심은 뛰어난 아이디어의 촉매입니다. 뛰어난 아이디어는 진보를 이루어 내죠. 지속가능한 발전을 위해 공헌할 수 있는 기회를 아래 채용 공고 (See our job vacancies) 를 통해 확인해 보십시오.

Advancing better. With Alfa Laval.