Cleaner and greener chartering for GasLog with Alfa Laval PureDry

GasLog Ltd. is an international owner, operator and manager of LNG carriers, providing support to international energy companies as part of their logistics chain. As a growth-oriented company focused on innovation, GasLog has chosen to equip three upcoming newbuilds with Alfa Laval PureDry, a high-speed separator for waste fuel recovery and liquid waste reduction

DATE 2023-11-28After receiving the new membrane-type LNG carriers in 2018 and 2019, GasLog will charter them to Shell. Being responsible for the fuel costs, Shell has been actively involved in the vessels’ design and first suggested the installation of PureDry. But while GasLog will not directly benefit from the potential fuel savings, the ship owner was keen to secure the environmental and performance advantages PureDry offers.

Doing away with liquid waste

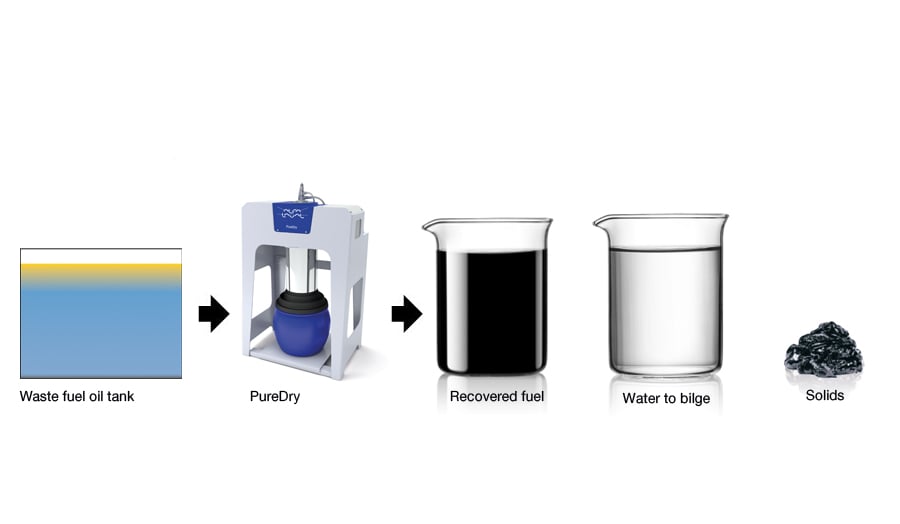

PureDry is an innovative high-speed disc-stack separator that can recover fuel of ISO 8217 quality from waste fuel oil. The system typically reclaims as much as 1-2% of a vessel’s HFO consumption, while simultaneously reducing sludge to a minimal amount of super-dry solids. All water is sent to the bilge water treatment system with an oil content of less than 1000 ppm.

The process reduces the waste volume by 99%, leaving no liquid waste whatsoever. The super-dry solids that remain, which are non-pumpable, can be easily landed as dry waste or incinerated.

Simpler waste management

Reducing the waste volume on board has obvious benefits for both GasLog and British Gas. Dealing with waste is a time-consuming and messy process for the crew that becomes faster and simpler when there is no sludge to pump.

“In LNG transport, discharging waste onto barges is less common than it is for bulk carriers,” notes George Raptakis, the Newbuilding and Projects Manager for GasLog. “But LNG operating patterns make it important to minimize the amount of solids for onshore disposal.”

Burning less makes more sense

In most cases, the waste fuel oil on GasLog vessels is incinerated. Using PureDry will greatly simplify the procedure, making it cleaner, easier and less frequently required.

As Raptakis explains, limiting waste incineration has clear – and green – operational advantages. “Reducing the incinerator’s operating time and making its operation smoother is a priority, both for environmental reasons and because it saves time for the crew,” he says. “Besides recovering HFO with PureDry, our charterer will use less additional fuel for incineration. That benefits all of us.”

A greener profile for owner and operator

Because the new vessels will have dual-fuel engines, their fuel savings with PureDry will be less significant than some other installations. “With LNG carriers burning boil-off gas, we do not expect the same level of savings as a VLCC or large container ship that uses HFO alone,” Raptakis admits. “However, we strive to provide our charterers with the best available technologies to operate our ships in a safe, efficient and environmentally friendly way.”

“GasLog has a mission to pursue growth through innovation, and that means more trade with more ships while using less energy and producing less waste,” Raptakis continues. “Along with our charterer British Gas, we continuously look for new technologies in the areas of energy efficiency and environmental performance. PureDry is in line with these goals.”

NEAR Marine

Learn more

다른 기사 읽기