Bulkers differ from other vessels in their ability to transport both dry and liquid cargo – which they often load and unload at different speeds. Their ballast water flow needs can be very small or very large, but they may not be the same during ballasting and deballasting. Alfa Laval PureBallast 3 offers solutions for all bulker types, and Alfa Laval has the bulker-specific experience to support the most complex bulker projects.

Bulkers often load their cargo at twice the rate they unload it, which means deballasting occurs at twice the ballasting speed. The PureBallast 3 bulker-fit configuration addresses this by dimensioning the reactor and filtration capacities for differentiated flows. Not only does it reduce OPEX and the already small system footprint, it also removes a significant amount of CAPEX.

Six of Star Bulk’s vessels already have PureBallast 3 systems, and now 37 of its Supramax, Ultramax, Panamax, Kamsarmax and Post Panamax bulkers will be retrofitted with bulker-fit configurations. “This is the appropriate solution in meeting the demanding trading requirements on these vessels,” says Nicos Rescos, Chief Operating Officer.

Briese Group has selected PureBallast 3 for roughly 100 vessels, including bulk carriers that will be equipped with bulker-fit configurations. “The bulker-fit configuration was a good compromise for our bulkers’ needs, since it combines a smaller footprint with lower CAPEX and OPEX,” says Adrian Beckmann of the Newbuilding and Project department.

A wide range of system advantages and dedicated technical solutions make PureBallast 3 the ideal choice for ballast water treatment on bulkers.

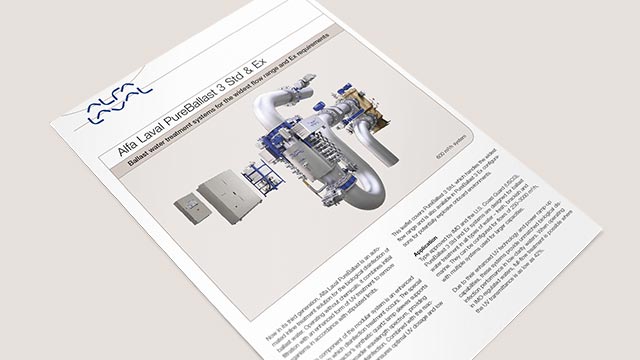

Your bulker may require up to hundreds of thousands of tons of ballast water – which means large ballast water flows. PureBallast 3 handles even very large flows with a small footprint and low power consumption, thanks in part to a 1500 m3/h reactor size. Single systems can handle up to 3000 m3/h, while dual systems can be used for coverage up to 6000 m3/h.

Existing bulkers need to be retrofitted with ballast water treatment systems by the time of their next renewal survey. However, they seldom have space allotted for it in their design. PureBallast 3 Compact Flex handles most flows and is flexibly built with loose components, making it the ideal system for saving space and resolving bulker retrofit challenges.

If you have a smaller bulker, there’s no reason to make big work of installing a ballast water treatment system. PureBallast 3 Compact is a convenient, skid-mounted solution that’s specially designed for smaller bulkers and other vessels with flow needs of 32–300 m3/h. Delivered as a skid-mounted module, it minimizes both footprint and pipework.

Many bulkers operate in coastwise service in USCG-regulated waters. If you have a relatively short time between United States ports, long ballast water holding times aren’t an option. PureBallast 3 now has a minimized holding time of just 2.5 hours – which is only needed when crossing between Captain of the Port Zones.

선박평형수 시스템 설치는 규정 준수를 위한 첫 번째 단계입니다. 모든 범위의 연간 서비스가 요구되는 규정 준수를 알파라발은 PureBallast 컴플라이언스 서비스 패키지를 통해 지원합니다.

The following links and downloads may be useful as you consider a PureBallast 3 solution for your bulker.

Learn more about the cost-saving PureBallast 3 bulker-fit configuration, which meets bulkers’ differentiated flow needs without overcapacity during ballasting.

Learn more about PureBallast 3 Std, which handles flows up to 3000 m3/h (6000 m3/h with dual systems) and has the broadest installation parameters.

Learn more about PureBallast 3 Compact Flex, the ideal solution for most vessels with ballast water flows up to 1000 m3/h. It arrives as loose components for complete installation freedom and the market’s smallest footprint.

Learn more about PureBallast 3 Compact, a convenient solution for smaller ballast water flows. It integrates the system into a plug-and-play module with a small footprint.

Find out why UV ballast water treatment today is often a smarter solution for large flows than electrochlorination.

The number of customers choosing PureBallast 3 for ballast water treatment on their bulkers continues to grow.

Columbia Shipmanagement will be the first to install PureBallast 3 systems with bulker-fit configurations. The savings in weight, footprint and equipment cost give the company further reasons for choosing UV ballast water treatment over electrochlorination.

Real-world experience confirms bulker operator Dowa Line’s choice of PureBallast 3. Shigetaka Inoue of the Marine Technical Department explains why simplicity makes the difference in ballast water treatment – and why Dowa Line will continue installing PureBallast 3 systems.

Polsteam and Nova Ship Tech SA have both signed major fleet agreements for the supply of PureBallast 3. Alfa Laval is providing the bulker operators with dozens of systems, the vast majority of which will handle large ballast water flows of more than 1000 m3/h.

Let’s talk about the specific challenges you face in ballast water treatment. With our many years of experience, we can guide you to the right PureBallast 3 solution for your bulker.