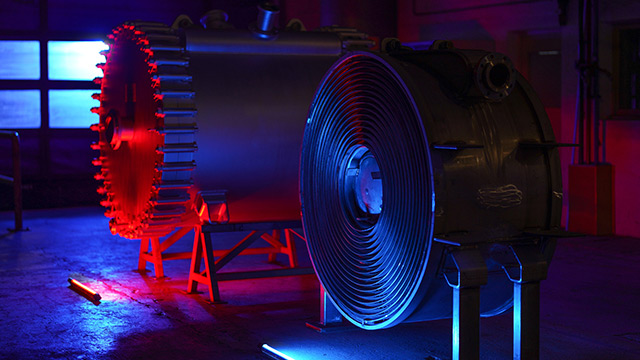

Sustain efficiency with our ten top tips for spiral heat exchangers

Just like all other industrial equipment, an Alfa Laval spiral heat exchanger requires regular maintenance to deliver high performance, maximum operational reliability, and energy efficiency.

In the videos below, we will share our ten top tips on how to perform maintenance safely and how to keep your heat exchanger in tip top condition. And you are of course always welcome to contact if you need our help.

Depressurize before opening

Never open a unit if one or both channels are pressurized. Any attempt to do so may cause personal injury and/or damage the unit and its surroundings.

Use the lifting lugs

Lift the unit by its lifting lugs and not by the connections or the cover lug.

Avoid pressure shocks

Open and close valves slowly to avoid water hammer from pressure surges during start-up and shutdown.

Ensure proper venting

Make sure that the unit is properly vented before start-up. We suggest you contact Alfa Laval to train your operators for optimum and reliable operations.

Monitor performance

Monitor the heat exchanger’s performance and pressure drop proactively in order to better plan cleaning and maintenance. This will enable you to further improve the sustainability of the system.

Alfa Laval can support you with a Performance Assessment that will determine the optimal cleaning intervals for your specific conditions.

Keep solids load within specifications

Always operate in accordance with the design rate to avoid thickening or clogging with fluids that contain solid particles.

Choose the optimum cleaning method for your heat exchanger

Use a cleaning method that is optimized for your heat exchanger. With cleaning-in-Place (CIP) or back flushing, you can avoid opening the unit. Alfa Laval’s service experts can help you determine and implement the best cleaning practices for you.

Change gaskets after opening

Change the cover gaskets every time you open the cover. Alfa Laval recommends that you keep a set of genuine spares designed for your unit in stock, so you can always be ready for maintenance.

Ensure the bolts are tightened

Tighten the unit as described in the installation manual during transportation or prolonged periods of shutdown. If not done properly, cover gaskets and/or hook bolts may loosen.

Flush and drain before long shutdowns

Flush and/or drain the heat exchanger in cases of a long shutdown, when using corrosive fluid, or if there is a risk of freezing.

The tips as a poster

Download our poster and follow our recommendation on how to keep your spiral heat exchanger in tip top condition.