Multicyclones and cyclonettes

Alfa Laval multicyclones and cyclonettes are used for starch washing, concentration, clarification and classification. Whatever challenge you face with your starch suspension, you can rely on our multicyclone systems to increase capacity, improve product quality or recover starch from process effluent while at the same time reducing maintenance costs. Perfect for use on starch suspensions from corn, wheat, tapioca, and potato to other starch-bearing crops, such as peas.

Fast, accurate separation of starch boosts product yield

- Optimum washing efficiency and low wash water consumption

- Easy to operate, long service lifetime

- Optional automated control

- Low maintenance costs due to no moving parts

- Easily expandable to increase capacity

Successful starch production requires getting the most out of raw materials and achieving the desired end-product quality through safe, cost-effective and sustainable processing. Rely on Alfa Laval multicyclones and cyclonettes for versatile, highly efficient centrifugal separation to wash starch and to concentrate, clarify or classify starch suspensions.

The difference in size and density between starch and impurities, like gluten and fine fibre, makes it possible to use centrifugal separation with cyclonettes for the applications mentioned above. The systems are easy to configure to meet your specific requirements and you can easily increase or reduce capacity whenever needed.

문서

Product leaflets

Multicyclones and cyclonettes

Degritting systems

Stone catcher

Applications

Two types of multicyclones are available:

- RH multicyclones with a large capacity radial matrix design

- PH multicyclones with a small to mid-range capacity design and parallel manifolded cyclonettes

The RH multicyclones are primarily used for starch washing in large capacity corn wet milling plants with grind rates above 900 ton/day corn. The PH multicyclones are used in all other applications.

The Alfa Laval cyclonettes are installed inside the multicyclone housing. Separation takes place when the feed pressure is converted to a rotation of the liquid as it enters the cyclonette. This generates the required g-force inside the cyclonette for fast and accurate particle separation.

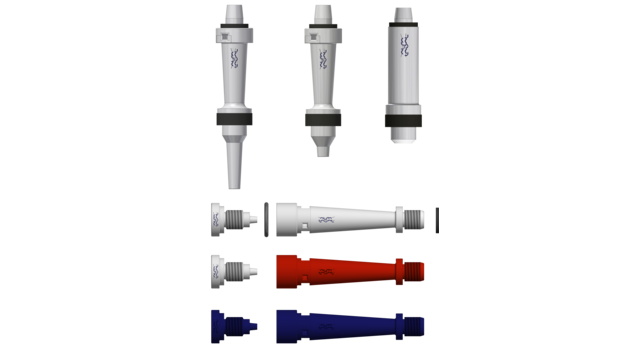

Several types of cyclonettes are available:

- 10 mm PC10 cyclonettes for washing, concentration and clarification of starch suspensions from corn, wheat and tapioca in PH type multicyclones.

PC10 cyclonettes can also be installed in the old Dorr-Oliver TM multicyclones. - 15 mm PC15 cyclonettes for washing, concentration and clarification of starch suspensions from potato in PH type multicyclones.

PC15 cyclonettes can also be installed in the old Dorr-Oliver TM multicyclones. - 10 mm RC10 cyclonettes used mainly for washing corn starch suspensions in the RH type multicyclones.

RC10 cyclonettes can also be installed in the old Dorr-Oliver radial matrix multicyclones. - 10 mm cyclonettes for the old Dorr-Oliver Clamshell multicyclones.

- 10 mm and 15 mm MOCL cyclonettes for the old Alfa Laval MOCL multicyclones.

Multistage starch washing system

The multistage starch washing system comprises several multicyclones installed in series. In front of each stage is a centrifugal feed pump.

The starch milk enters the first washing stage. It is washed in a counter-current stream of water and leaves at the underflow of the last stage as concentrated purified starch milk.

The underflow of a given washing stage contains the concentrated starch milk and the overflow entrains the impurities and some recycled starch. The underflow of a given stage is together with the overflow of the second to next stage transferred to the feed pump of the intermediate stage. In this way, the starch milk entering the system in the first stage is washed by dilution and concentration in the subsequent stages and leaves the system via the underflow of the last stage.

The wash water entering the system ahead of the last washing stage leaves the system via the overflow of the first washing stage carrying the impurities such as soluble protein, gluten and fine fibre out of the system.

The first stage overflow also contains a certain amount of starch that is recycled to the upstream process.