HVO pretreatment systems

Increasing demand for hydrotreated vegetable oil (HVO) calls for proven, reliable processes. Renewable fuel producers can rely on comprehensive Alfa Laval HVO pretreatment systems to produce renewable diesel and sustainable aviation fuels from the widest range of fats and oils, including recycled animal fat and used cooking oils. Our robust, proven solutions produce feedstock free from impurities, maximising your feedstock yields and reducing unplanned operational downtime.

Your trusted partner for HVO pretreatment

- Flexible pretreatment systems that can process the widest range of feedstocks available now and in the future

- High yields of high-quality pretreated fats and oils

- Maximum availability of your HVO units by minimising unplanned downtime

- Leading technologies for wastewater treatment and water recycling

- Global service network with local presence

Our expert advisors are with you at every stage of the HVO pretreatment journey, from prepurchase, to design and delivery, ongoing monitoring and servicing. Alfa Laval has a deep understanding of hydroprocessing oils and fats into renewable fuels based on decades of experience with pretreatment systems for edible oil and petroleum refining. Alfa Laval HVO pretreatment systems are optimized to remove impurities and reduce clogging, helping to prolong the lifespan of the hydrotreating catalyst and maximising your ROI.

Based on proven edible oil refining and petroleum refining technologies, our reliable HVO pretreatment systems optimize stand-alone facilities for HVO production, as well as oil refineries converted into HVO production facilities.

Renewable fuels production

Find out how smart design choices can help improve sustainability and profitability in plants producing renewable diesel.

사용 방법

Physical refining process or chemical refining process

Alfa Laval biofuel pretreatment systems include both physical refining processes and chemical refining processes. For HVO the preferred process is physical refining, involving special degumming and/or enzymatic degumming, adsorption, and deacidification (if required). The chemical refining process is mainly used in pretreatment of traditional biodiesel (fatty acid methyl esters), where Alfa Laval also has a vast experience.

Removal of phosphorous and trace metals

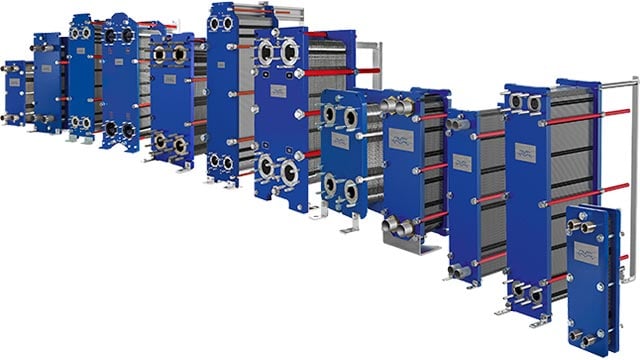

To remove phosphorous and trace metals, the fats and oils (tallow, soy, rapeseed, distillers, corn oil, etc.) as well as recycled animal fat and used cooking oils undergo degumming with acid treatment (citric or phosphoric acid), and washing and adsorption using bleaching clays or similar with Alfa Laval high speed separators and plate heat exchangers.

Chloride removal

Chlorides, if present, are removed at the front-end of the process by water washing and onward processing in Alfa Laval high speed separators and plate heat exchangers.

Polyethylene removal

Polyethylene, if present such as in some tallow qualities, can be removed by crystallization and filtration.

Fatty acid removal

In some cases, the fatty acid content must be limited to eliminate the risk of corrosion due to metallurgy in the HVO section. This can be achieved by co-processing a blend of feedstocks, if needed, as well by steam stripping the oil under vacuum conditions using an Alfa Laval Aalborg High Pressure Natural Circulation boiler, welded and gasketed plate heat exchangers and an Alfa Laval stripping column.

Key components used in the HVO pretreatment systems

응용 분야

서비스

Food system services

알파라발 푸드 시스템 서비스는 공정 성능을 극대화하여 시스템의 성능을 확장하는 데 도움이 됩니다. 이를 통해 얻을 수 있는 잇점은 아래와 같습니다.

- 지속적인 운영 개선으로 경쟁 우위 유지

- 가동 시간, 최적화 및 가용성에 집중

- 푸드 시스템의 수명 주기 전반에 걸쳐 투자 수익 극대화